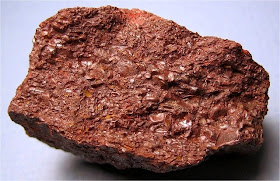

What is iron ore?

The iron ore deposits are found in sedimentary rocks. They are formed by the chemical reaction of iron and oxygen mixed in the marine and fresh water. The important iron oxides in these deposits are hematite and magnetite. These are ores from where iron is extracted.

Iron ore formation

Iron ore formation

The iron ore formation started over 1.8 billion years ago when abundant iron was dissolved in the ocean water which then needed oxygen to make hematite and magnetite. The oxygen was provided when the first organism capable of photosynthesis began releasing oxygen into the waters. This oxygen combined with dissolved iron to form hematite and magnetite. These then deposited on the ocean floor abundantly which are now known as banded iron formation.

Sources of iron ore

Metallic iron is basically obscure on the surface of the Earth aside from as iron-nickel composites from shooting stars and exceptionally uncommon types of profound mantle xenoliths. Albeit iron is the fourth most plentiful component in the Earth's covering, containing around 5%, by far most is bound in silicate or all the more seldom carbonate minerals. The thermodynamic obstructions to isolating unadulterated iron from these minerals are imposing and vitality serious, in this way all wellsprings of iron utilised by human industry misuse relatively rarer iron oxide minerals, fundamentally hematite.

Before the modern upheaval, most iron was acquired from broadly accessible goethite or lowland mineral, for instance amid the American Revolution and the Napoleonic Wars. Ancient social orders utilised laterite as a wellspring of iron mineral. Truly, a great part of the iron mineral used by industrialised social orders has been mined from transcendently hematite stores with grades of around 70% Fe. These stores are usually alluded to as "immediate delivery minerals" or "characteristic metals". Expanding iron metal request, combined with the consumption of high-review hematite minerals in the United States, after World War II prompted to improvement of lower-review press metal sources, basically the usage of magnetite and taconite.

Press metal mining strategies change by the kind of mineral being mined. There are four fundamental sorts of iron-metal stores worked right now, contingent upon the mineralogy and topography of the metal stores. These are magnetite, titanomagnetite, monstrous hematite and pisolitic ironstone stores.

Banded iron formations

Banded iron formations (BIFs) are sedimentary rocks containing over 15% iron made dominatingly out of daintily had relations with iron minerals and silica (as quartz). Banded iron formations happen only in Precambrian shakes, and are regularly feebly to strongly transformed. Banded iron formations may contain press in carbonates (siderite or ankerite) or silicates (minnesotaite, greenalite, or grunerite), however in those mined as iron metals, oxides (magnetite or hematite) are the chief iron mineral. Banded iron formations are known as taconite inside North America.

The mining includes moving enormous measures of metal and waste. The waste comes in two structures, non-metal bedrock in the mine (overburden or inter-burden privately known as mullock), and undesirable minerals which are a characteristic part of the metal shake itself (gangue). The mullock is mined and heaped in waste dumps, and the gangue is isolated amid the beneficiation procedure and is expelled as tailings. Taconite tailings are for the most part the mineral quartz, which is artificially latent. This material is put away in vast, directed water settling lakes.

Magnetite ores

The key monetary parameters for magnetite mineral being financial are the crystallinity of the magnetite, the review of the iron inside the joined iron arrangement have shake, and the contaminant components which exist inside the magnetite think. The size and strip proportion of most magnetite assets is immaterial as a united iron development can be many meters thick, augment several kilometres along strike, and can undoubtedly come to more than three billion or more huge amounts of contained metal.

The normal review of iron at which a magnetite-bearing united iron arrangement gets to be distinctly financial is around 25% iron, which can for the most part yield a 33% to 40% recuperation of magnetite by weight, to create a move evaluating in abundance of 64% iron by weight. The average magnetite press metal focus has under 0.1% phosphorus, 3–7% silica and under 3% aluminium.

Presently magnetite press mineral is mined in Minnesota and Michigan in the U.S., Eastern Canada and Northern Sweden. Magnetite bearing united iron development is presently mined broadly in Brazil, which sends out huge amounts to Asia, and there is an early and huge magnetite press mineral industry in Australia.

Magmatic magnetite ore deposits

Occasionally granite and ultrapotassic igneous rocks segregate magnetite crystals and form masses of magnetite suitable for economic concentration. A few iron ore deposits, notably in Chile, are formed from volcanic flows containing significant accumulations of magnetite phenocrysts. Chilean magnetite iron ore deposits within the Atacama Desert have also formed alluvial accumulations of magnetite in streams leading from these volcanic formations.

Some magnetite skarn and hydrothermal deposits have been worked in the past as high-grade iron ore deposits requiring little beneficiation. There are several granite-associated deposits of this nature in Malaysia and Indonesia.

Other sources of magnetite iron ore include metamorphic accumulations of massive magnetite ore such as at Savage River, Tasmania, formed by shearing of ophiolite ultramafics.

Another, minor, source of iron ores are magmatic accumulations in layered intrusions which contain a typically titanium-bearing magnetite often with vanadium. These ores form a niche market, with specialty smelters used to recover the iron, titanium and vanadium. These ores are beneficiated essentially similar to banded iron formation ores, but usually are more easily upgraded via crushing and screening. The typical titanomagnetite concentrate grades 57% Fe, 12% Ti and 0.5% V2O5.

Beneficiation of iron ore

Lower-grade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities. The results, high quality fine ore powders, are known as fines.

Magnetite

Magnetite is attractive, and subsequently effortlessly isolated from the gangue minerals and equipped for creating a high-review think with low levels of polluting influences.

The grain size of the magnetite and its level of mixing together with the silica groundmass decide the pound size to which the stone must be comminuted to empower effective attractive partition to give a high immaculateness magnetite focus. This decides the vitality inputs required to run a processing operation.

Mining of united iron developments includes coarse smashing and screening, trailed by unpleasant pounding and fine granulating to comminute the mineral to the point where the solidified magnetite and quartz are sufficiently fine that the quartz is deserted when the resultant powder is passed under an attractive separator.

By and large most magnetite grouped iron arrangement stores must be ground to in the vicinity of 32 and 45 micrometers keeping in mind the end goal to deliver a low-silica magnetite think. Magnetite focus evaluations are by and large in overabundance of 70% iron by weight and generally are low phosphorus, low aluminum, low titanium and low silica and request a top notch cost.

Hematite

Because of the high thickness of hematite in respect to related silicate gangue, hematite beneficiation as a rule includes a blend of beneficiation strategies.

One strategy depends on passing the finely smashed metal over a slurry containing magnetite or other specialist, for example, ferrosilicon which expands its thickness. At the point when the thickness of the slurry is appropriately adjusted, the hematite will sink and the silicate mineral parts will coast and can be evacuated.

Uses

The primary use of iron ore is in the production of iron. Most of the iron produced is then used to make steel. Steel is used to make automobiles, locomotives, ships, beams used in buildings, furniture, paper clips, tools, reinforcing rods for concrete, bicycles, and thousands of other items. It is the most-used metal by both tonnage and purpose.